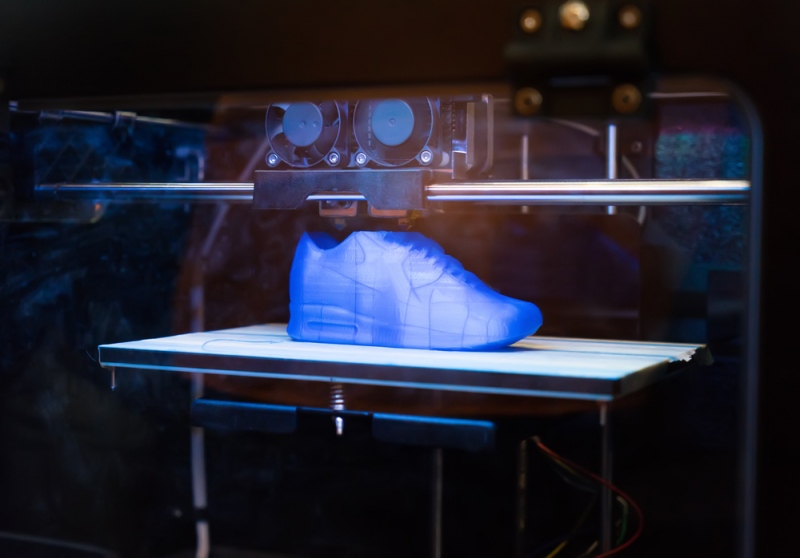

In contrast with traditional manufacturing, 3D printing is the creation of three-dimensional objects using digital files and specific materials such as resins, plastics, biomaterial, and metallic powders, among others. These techniques are based on the consolidation of materials supplied in a powdered format. The uses of these types of printers vary and include the ability to build inexpensive prototypes for the rapid construction of any object that can be used in industries such as architecture, aviation, construction, product design, and others.

This new type of manufacturing allows experts in the field to create forms and structures that are hard or expensive to obtain using traditional processes. The technique not only offers new alternatives for the development of prototypes for innovations or ideas, it also allows companies to personalize products, thus creating the ability to tailor to smaller segments or respond to specific market needs in smaller quantities at low prices. These alternatives in rapid production are precise. Therefore, such conditions permit companies to optimize their inventories and increase the efficiency of cost management.

The use of 3D printers can be considered a disruptive technology that has revolutionized industries given than sectors such as biomedicine, aerospace, avionics, and others can generate value-added prototypes and functional pieces. For example, the added value that the technology provides toward Additive Manufacturing includes:

- Rapid manufacturing from initial idea to final concept

- Increased profitability in the manufacturing of prototypes or small productions

- Product personalization at low costs

- Ability to repair high-value pieces

Industries began using additive manufacturing equipment and technologies toward the end of the 1970s. However, after 2012, industries began using such technologies for purposes that are beyond simple product samples and started visualizing the wide range of applications and the impact that 3D printing has on different sectors. For example, in biomedicine, these new manufacturing techniques can be used for the development of organs for transplant. Experts estimate that the technology will generate more than 26.5 billion dollars by 2021.

Businesses have witnessed growth in the use of 3D printing and additive manufacturing and how its adoption has created specific benefits in each respective sector of the economy. In the Industrial Manufacturing and Automotive sector, for example, companies have seen the consolidation of components toward a single complex piece, the development of production tools, the creation of components and replacement parts, and a reduction in the development time of new products. In the Electronics sector, the industry has witnessed the development of printed circuits using conductive ink and the manufacturing of electromechanical components using three-dimensional blueprints.

Cities such as Dubai have made substantial investments in their next innovation hub. For example, the start-up company Cazza announced that they would initiate the construction of a skyscraper using the technology by 2023. For this, the company created an innovation called Minitank that can build 200 square meters of concrete per day. The device allows a 50% reduction in construction time, compared to conventional methods.

MIT’s interdisciplinary team, developed by Skylar Tibbits, a computational architect, has been developing the concept of 4D printing. In 4D printing, biological and physical materials are used and programmed to obtain high adaptive capabilities. These materials can adapt to different environments and have additional properties such as the ability to repair and transform themselves. This technology has the potential to revolutionize industries such as medicine, but experts also believe that the technology can be applied to practically all sectors of the economy.

As these technologies continue to evolve, the applicability in business industries will become more apparent. Even though companies are seeing cost savings and productivity increases by investing in 3D printing, the potential for growth remains high, as the cost of purchasing these innovations reduces to the point where it becomes accessible to smaller organizations. For now, smaller organizations unable to invest in the technology can look for companies that specialize in 3d printing service to remain competitive.